In modern industrial environments, predictive maintenance is becoming an essential strategy to optimize operational efficiency and prolong equipment lifespan. Among the various technologies supporting predictive maintenance, vibration analysis stands out as one of the most effective and proven methods.

What is Predictive Maintenance?

Unlike scheduled maintenance or reactive repairs, predictive maintenance enables real-time condition monitoring to detect potential mechanical issues before they lead to equipment failure. The benefits include:

- Preventing unexpected downtime

- Enabling planned maintenance and repair

- Reducing maintenance costs and resource consumption

Why is Vibration Analysis Important?

All rotating machinery generates vibrations during operation. These vibrations contain valuable information about the internal mechanical state. Through vibration analysis, technicians can identify early signs of:

- Unbalance

- Misalignment

- Mechanical looseness

- Bearing and gearbox faults

Unlike other condition monitoring methods such as ultrasound or thermography, vibration analysis provides clear, quantifiable insights into the severity and location of mechanical issues.

How Does It Work?

A vibration analysis system typically includes:

- Acceleration sensor – captures vibration signals and converts them into voltage

- Vibration meter or analyzer – processes the signal and displays acceleration (g) or velocity (mm/s)

- Data management software – such as ADASH DDS, which allows for measurement organization, trending, and route planning

Measurement process:

- Place the sensor at a measurement point (usually on a bearing housing)

- The sensor converts mechanical vibration into an electrical signal

- The signal is transmitted to the analyzer, which displays the vibration values

Key Considerations for Accurate Vibration Measurement

- Ensure consistent measurement points, properly prepared (flat, clean, rust- and paint-free surfaces)

- Use measurement pads and magnetic bases for reliable contact

- Optimal measurement direction: radial at 45° and one axial point near shaft couplings

- Avoid measuring on fan covers or uneven surfaces, which distort vibration readings

What Should You Measure?

To assess machine condition effectively, two primary measurements are essential:

- Overall Velocity (mm/s) – Measured in the 10–1000 Hz range, it reflects general mechanical faults (e.g., unbalance, looseness)

- Overall Acceleration (g) – Measured in the 500–16000 Hz range, ideal for detecting high-frequency bearing faults

A Proactive Mindset Matters

While vibration analysis is powerful, true maintenance reliability comes from proactive habits:

- Know your machines well

- Keep them clean and visually inspect for leaks or cracks

- Listen for unusual noises

- Share findings with colleagues using the Buddy System – early communication can prevent failures and even save lives

Conclusion

Vibration analysis is the cornerstone of a modern predictive maintenance program. With the right equipment, structured data management, and a vigilant maintenance culture, your business can improve machine reliability, lower operational costs, and prevent critical failures before they happen.

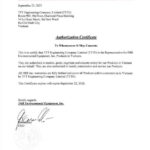

TTT ENGINEERING COMPANY LIMITED – Official Distributor of ADASH in Vietnam

TTT ENGINEERING COMPANY LIMITED is the exclusive authorized distributor of ADASH in Vietnam — a global leader in vibration analysis and predictive maintenance technologies.

We provide:

- Genuine ADASH vibration monitoring equipment

- Complete system setup with DDS software and training

- Expert consulting tailored to your machine condition monitoring needs

👉 Looking to build a smart maintenance strategy?

👉 Need support selecting the right vibration diagnostics tools?

👉 Want to prevent unexpected machine failures and downtime?

✅ Contact TTT ENGINEERING COMPANY LIMITED today:

📞 Hotline: 0903 929 505 (Mr. Thi)

📧 Email: info@tttengineering.net

🌐 Website: www.tttengineering.net

Invest in reliability today — prevent costly failures tomorrow.

Let TTT ENGINEERING COMPANY LIMITED be your trusted partner on the path to smarter maintenance.